Armor – Shield

Manufacturing Process

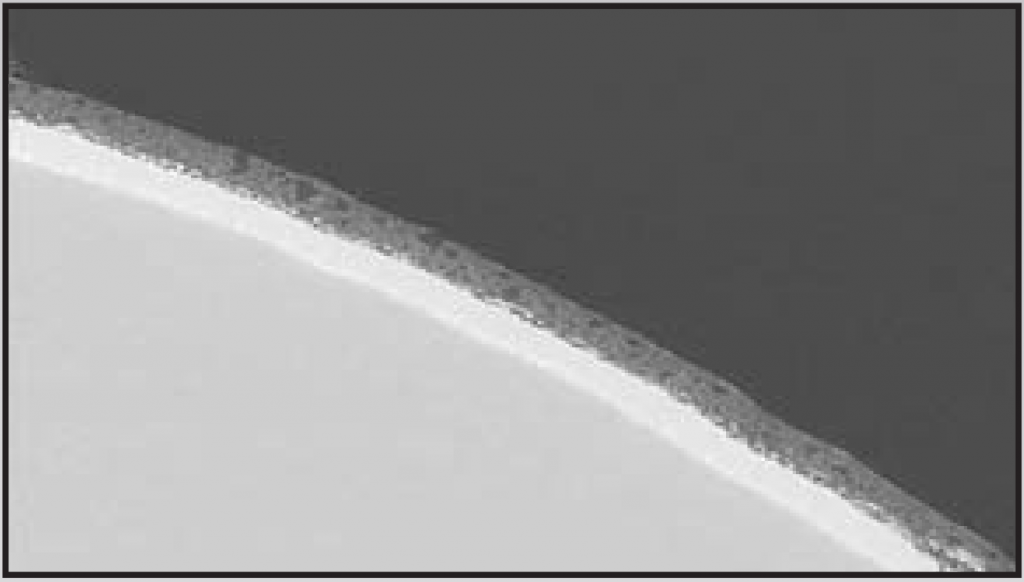

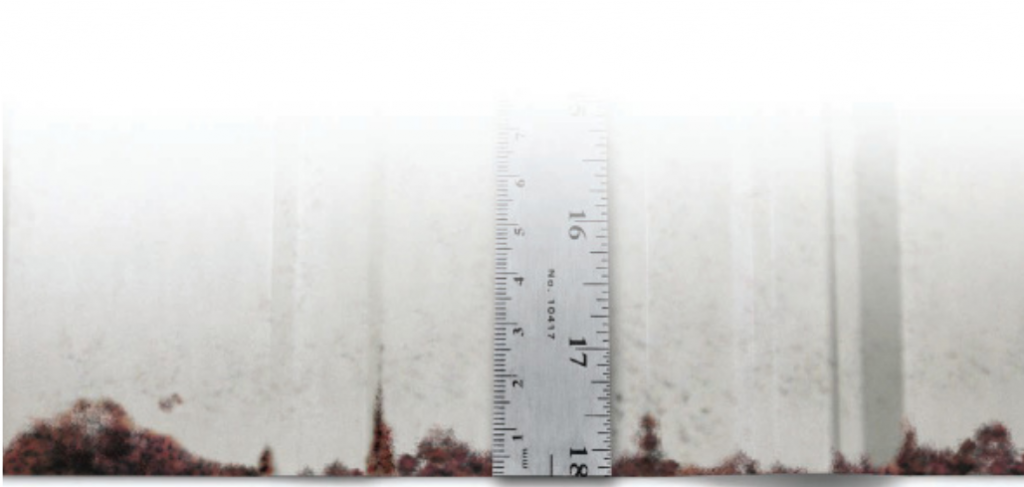

Incorporates Warm Roll-Forming of prepainted Sheet Steel with clear coated edges.

In a recent study, U.S. Steel has demonstrated that warm roll-forming not only improves the formability of the paint film, but also improves the fomability of the underlying metal coating.

(U.S. Steel Technical Bulletin, Sept. 2005)

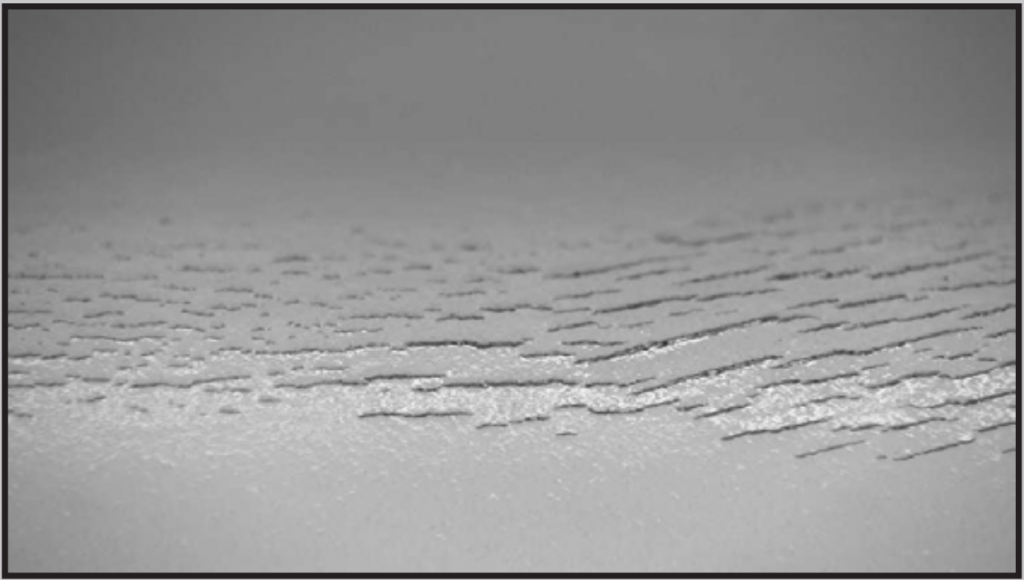

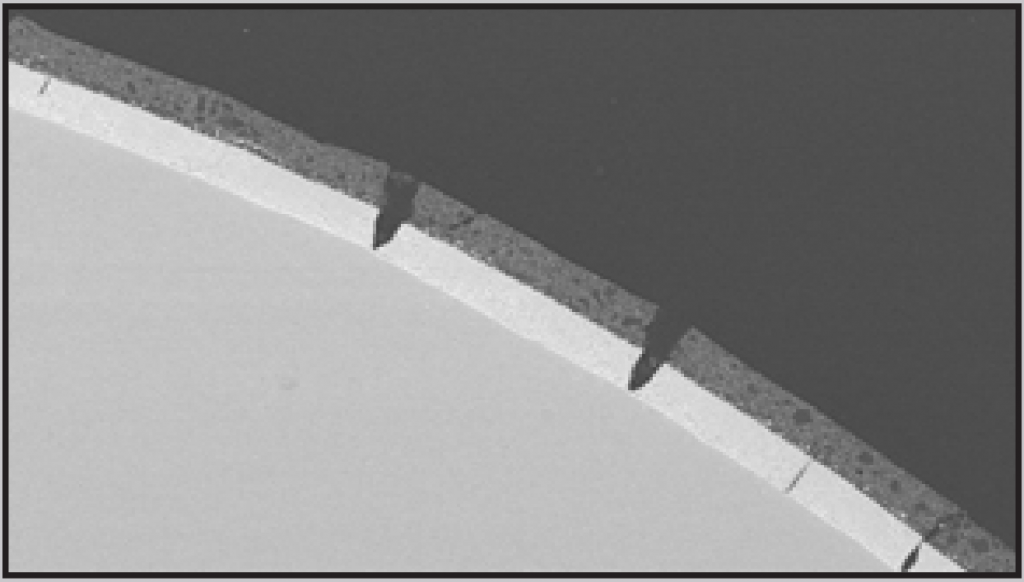

Cold Formed Steel

Heat Formed Steel

It is believed that tension-bend cracking on the prepainted GALVALUME sheet could be virtually eliminated by using flexible paint systems and warm roll-forming practices

(U.S. Steel Technical Bulletin, Sept. 2005)

*The clear coating of panel edges protects the open edge, while the galvanic reaction is taking place, for a more permanent protection.*

Warm Roll Forming

All of Fabco’s The Metal Center steel coils are kept in the “Hot Box”, a heated room which stays at 85 degrees or greater all year.

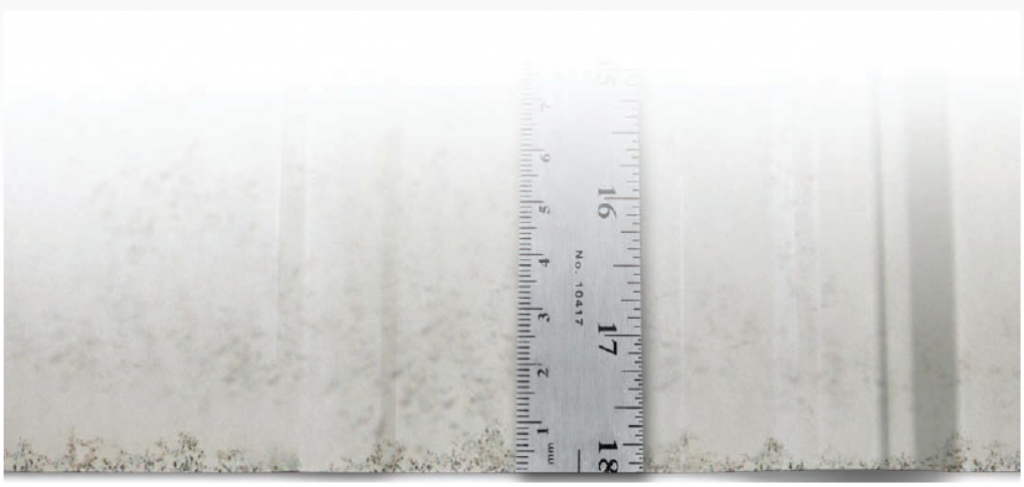

Pre-Painted Galvalume vs. Pre-Painted Galvanized

Comparison of Corrosion

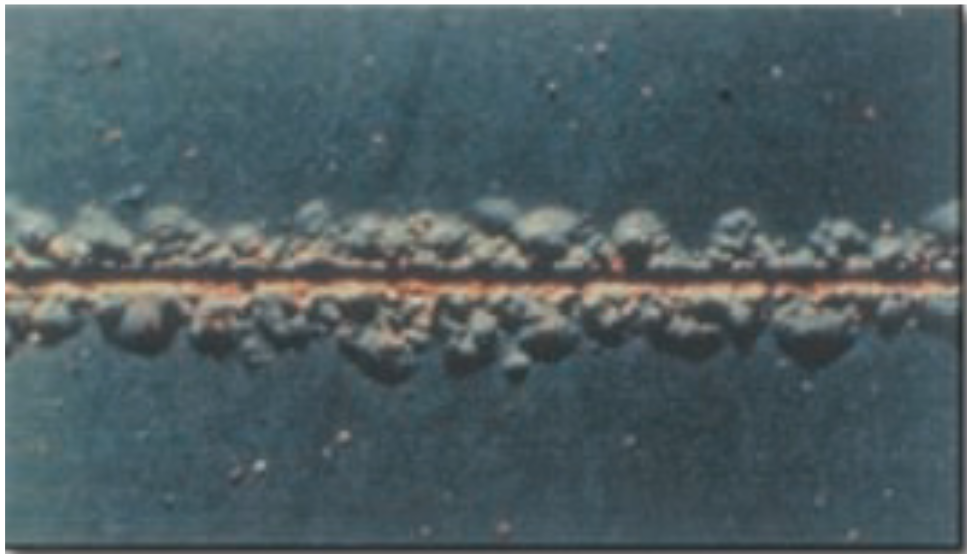

Pre-Painted Galvalume (10 yrs)

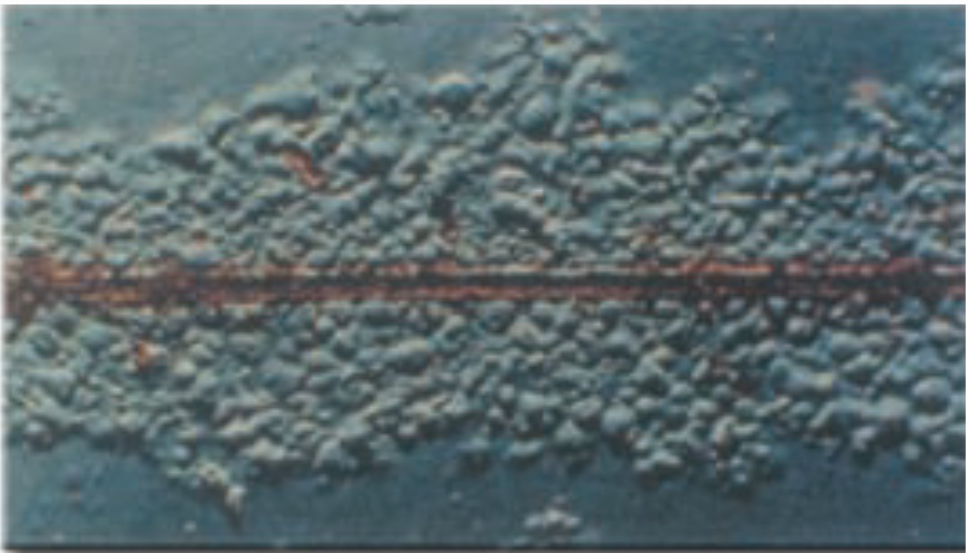

Pre-Painted Galvanized (9 yrs)

Comparison of Corrosion on a Scratch Site

Galvalume

Galvanized